By Lee Anne Spear

M.A. ’23, Museum Studies

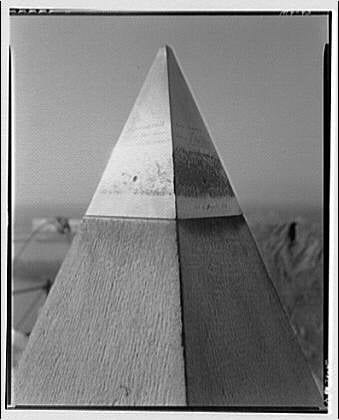

It is unsurprising that the Washington Monument, similar to architecture all around the capital, was built with marble. What may surprise you is that the capstone resting on the top of the monument is made of a $225 pyramid of aluminum. At just under nine inches tall and 100 ounces, the capstone was the largest piece of solid aluminum when it was made in 1884. While we see aluminum as a cheap and commonplace material today, it wasn’t always readily available. Aluminum is abundant in the Earth’s core but does not occur in metallic form naturally. In 1884 aluminum was incredibly difficult and expensive to process. Costing $1.10 per ounce, aluminum was considered as valuable as silver. When the U.S. government was determining what the capstone should be made of, they wanted a material that would reflect the elegance and strength of the first president. The world’s newest precious metal seemed the perfect choice. On December 6, 1884, the aluminum capstone was placed, bringing an end to the 36-year construction of the 555-foot obelisk. Inscribed on the capstone is the Latin phrase “Laus Deo”, meaning “Praise be to God.”

Less than two years after the placement of the capstone, the value of aluminum dropped dramatically when a young chemist discovered a simpler method of processing the metal. It was also discovered that the capstone was not pure aluminum, instead aluminum only made up 97.75% with the rest being cheaper metals. Then in 1941 the capstone was volunteered for an aluminum scrap drive in support of World War II efforts. Despite these developments the aluminum capstone remains in place today and is considered to be in good shape. After the completion of the monument D.C. Building Code was updated to state that the Washington Monument is to be the tallest structure in the city, no future buildings can surpass its 555 feet.

Right: Harper’s Weekly 1884, page 839. Hand-colored. Main view shows the setting of the capstone while the top of the print has the portraits of three men connected with the project: Gen. Gershom Mott, Col. Thomas L. Casey, and Reuben R. Springer (AS 182).